Prefabricated metal buildings deliver durable, cost-effective, and customizable steel structures for residential, agricultural, and commercial uses across North Carolina, South Carolina, and Virginia. Whether you need a ready-to-assemble metal garage kit, a turnkey pre-engineered barn, or a fully tailored workshop, understanding available types, costs, benefits, and customization options ensures you invest wisely. This guide covers core definitions and product categories, detailed pricing factors, performance advantages, bespoke design possibilities, regional code requirements, application-specific features, and practical next steps to secure your ideal structure. By the end, you will know which prefabricated metal building aligns with your storage, utility, or business goals and how Hinton Buildings streamlines selection, financing, and installation.

What Are Prefabricated Metal Buildings and Their Key Types?

Prefabricated metal buildings are factory-fabricated steel structures designed to minimize on-site labor while maximizing strength and longevity. These buildings arrive in precisely engineered components that bolt together quickly, offering consistency in quality and reduced construction time. Their modular design allows homeowners, farmers, and businesses to select from a variety of styles that meet specific spatial and functional requirements.

What Defines a Prefabricated Metal Building?

A prefabricated metal building is a pre-cut, pre-drilled steel frame and panel system manufactured in controlled factory conditions. This approach ensures uniform gauge steel, precision alignment, and welded connections that resist wind, fire, pests, and corrosion. Uniform production methods yield predictable performance metrics, and controlled finishing processes protect coatings and paints—resulting in structures that stand up to heavy snow, hurricanes, and daily wear with minimal maintenance.

What Are the Main Types of Metal Buildings?

| Building Category | Typical Features | Common Uses |

|---|---|---|

| Metal Garages | Clear-span bays, roll-up doors, sidewalls | Vehicle storage, workshop space |

| Steel Barns | Wide-span framing, large doors, hay loft options | Agricultural equipment housing, livestock stalls |

| Commercial Structures | High eave heights, optional mezzanines, office bays | Warehouses, retail shops, distribution centers |

| Agricultural Sheds | Gabled roofs, adjustable leg heights, lean-to designs | Fruit, vegetable, or tobacco storage; covered machinery parking |

Each building type addresses unique load requirements and interior configurations, guiding you toward the right steel solution for your project.

How Do Metal Building Kits Differ from Pre-Engineered Steel Buildings?

Metal building kits provide all structural components—steel framing, panels, fasteners, and trim—shipped to the site for owner or contractor assembly. By contrast, pre-engineered steel buildings include factory-assembled subunits, foundation design, and optional installation services, delivering a turnkey approach that requires minimal on-site work beyond laying a concrete pad.

APX Construction Group, Pre-Engineered Metal Buildings Average Cost per Square Foot, [2022]

Pre-Engineered Metal Buildings Average Cost

Pre-engineered metal buildings (PEMBs) generally cost between $10 and $25 per square foot, but this can vary based on several factors. The cost of a 20,000 sq ft warehouse can range from $240,000 to $380,000.

Which Applications Suit Prefabricated Metal Buildings Best?

- Residential: Detached garages, workshops, hobby spaces

- Agricultural: Barns, equipment sheds, livestock shelters

- Commercial: Warehouses, retail canopies, workshops

This versatility ensures that any user—from a homeowner needing extra storage to a business requiring warehouse capacity—finds a suitable steel building solution.

How Much Do Prefabricated Metal Buildings Cost?

Estimating the cost of a prefabricated metal building involves several variables, including size, customization, insulation, site preparation, and installation method. Recognizing these factors lets you budget accurately and compare options.

What Is the Average Price per Square Foot for Metal Building Kits and Turnkey Installations?

Prefabricated metal building kits typically range between $15 and $25 per square foot. Fully installed (turnkey) steel buildings average $24 to $43 per square foot, depending on foundation requirements, insulation level, and delivery distance. These averages reflect base model configurations without accessories.

Buildings Guide, Metal Building Prices | Cost per Square Foot & Estimator, [2025]

Metal Building Prices

Prefabricated metal building kits typically range from $15 to $25 per square foot, while fully installed (turnkey) steel buildings average $24 to $43 per square foot. These costs are influenced by factors such as size, customization, and installation method.

What Factors Affect the Cost of Metal Buildings?

- Building Size and Span – Larger clear-span widths command more steel and engineering.

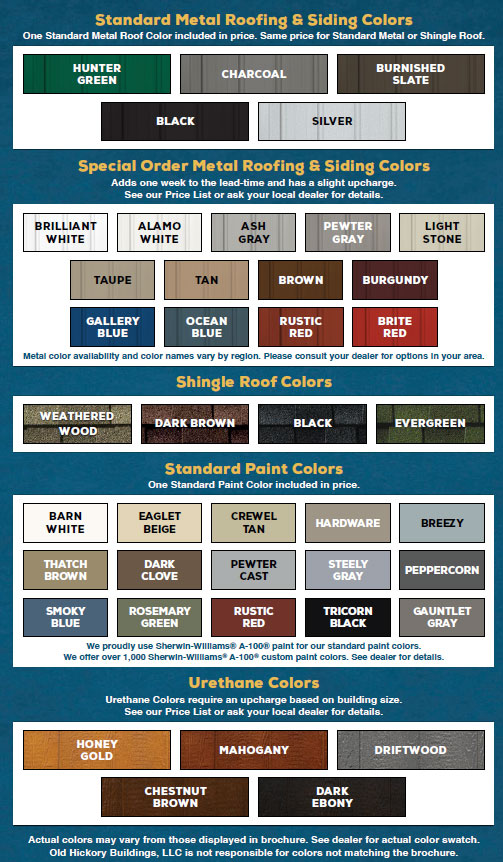

- Customization Level – Specialty roof styles, color palettes, and window layouts add material and labor costs.

- Insulation and Interior Finish – Insulated panels and interior liners increase upfront cost but deliver long-term energy savings.

- Foundation and Site Prep – Excavation, concrete footings, and grading affect ground-work expenses.

- Delivery and Installation – Remote locations and professional assembly services raise logistics and labor fees.

Understanding how these factors interrelate clarifies cost-benefit trade-offs between basic kits and full-service builds.

Are Financing and Rent-to-Own Options Available for Metal Buildings?

Many manufacturers and third-party lenders offer financing programs tailored to prefabricated steel structures, including 0% down, 12- to 60-month loan terms, and rent-to-own arrangements. These options spread capital expenditure over a defined schedule, making larger investments feasible for homeowners, farmers, and businesses alike.

Newmart Builders, Metal Building Financing, [n.d.]

Metal Building Financing Options

Financing options for metal buildings include home improvement loans, construction loans, and agricultural financing. These options can provide flexible terms and make larger investments feasible.

How to Compare Costs Between Prefabricated Metal Buildings and Traditional Construction?

Prefabricated steel often costs 20–30% less than wood-framed or masonry builds when factoring in labor savings, reduced waste, and faster completion. Traditional construction may incur higher framing, sheathing, roofing, and finishing expenses, as well as extended site labor. In regions with high labor rates, a prefabricated metal building typically delivers a superior price-performance ratio.

What Are the Benefits of Choosing Prefabricated Metal Buildings?

Prefabricated metal buildings offer multiple performance advantages, ranging from structural resilience to environmental sustainability. These benefits translate into lower operating expenses and lasting value for owners.

How Durable and Long-Lasting Are Steel Buildings?

Steel buildings resist termites, rodents, mold, mildew, and fire while withstanding extreme weather events. Rust-resistant coatings and high-tensile steel framing contribute to a lifespan exceeding 50 years, and many suppliers back this with 20- to 40-year corrosion and material warranties.

Build Using Steel, Durability, [n.d.]

Durability and Longevity of Steel Buildings

Steel buildings are known for their durability and can last for over 50 years with proper maintenance. They are resistant to pests, fire, and extreme weather events, contributing to their long lifespan.

How Do Metal Buildings Offer Energy Efficiency and Low Maintenance?

Metal building systems integrate reflective roof coatings, insulated panel walls, and sealed closures to minimize heating and cooling loads. Owners report up to 60% lower HVAC costs compared to conventional designs, and routine maintenance is limited to periodic inspection of sealants and gutters.

Foothill Country Sheds And Shelters, Practical Tips To Optimize The Energy Performance Of Your Metal Building, [2024]

Energy Efficiency in Metal Buildings

Metal buildings can be energy-efficient through the use of reflective roof coatings, insulated panel walls, and sealed closures, which minimize heating and cooling loads. Owners report up to 60% lower HVAC costs compared to conventional designs.

What Makes Metal Buildings Environmentally Friendly?

Steel is the world’s most recycled material and continues to contain an average of 25–35% recycled content. Prefabrication reduces on-site waste, and durable finishes lengthen replacement cycles—cutting resource consumption and landfill impact over the building’s lifecycle.

Ceco Building Systems, Sustainable Metal Buildings – Energy Efficient Steel Buildings, [n.d.]

Eco-Friendly Benefits of Metal Buildings

Metal buildings are environmentally friendly due to the high recyclability of steel and aluminum, reducing waste and resource consumption. They also offer energy efficiency through insulation and reflective roof coatings.

How Quickly Can Prefabricated Metal Buildings Be Installed?

Factory-engineered components allow erection rates of up to 5,000 square feet per week with a qualified crew. Compared to traditional builds that span months, a steel structure can be weather-tight in days, accelerating interior fit-out or occupancy.

How Can You Customize Your Prefabricated Metal Building?

Extensive customization sets prefabricated steel apart from generic kit options. From roof styles to insulation, every element adapts to your aesthetic preferences and functional demands.

What Roof Styles, Colors, and Materials Are Available?

Steel roofs come in gable, single-slope, horizontal-rib, and standing-seam profiles, with color offerings spanning standard neutrals to bold accent hues. Textured finishes and anti-condensation liners broaden design flexibility while managing interior climate.

K&G Metals Inc, 3 Ways to Customize Your Steel Building, [n.d.]

Customization Options for Metal Buildings

Metal buildings offer extensive customization options, including various roof styles, colors, door and window choices, and insulation options. These features allow for tailored designs to meet specific aesthetic and functional needs.

How Do Door, Window, and Opening Choices Affect Functionality?

Roll-up and sectional overhead doors, walk-in entry frames, ventilation louvers, and operable windows influence access, airflow, and natural light. Strategic placement of these openings ensures optimal building performance for storage, livestock comfort, or human workspaces.

What Insulation Options Enhance Comfort and Efficiency?

Insulation solutions range from single-layer blanket insulation to sandwich-panel walls and roof systems with R-values up to R-30. Each choice balances thermal performance, condensation control, and budget considerations to reduce long-term energy costs.

Can You Use a 3D Configurator to Visualize Custom Designs?

Interactive digital planners allow you to configure dimensions, colors, roof profiles, and accessories in real time. This tool helps you preview aesthetic and functional choices before finalizing orders and streamlines communication of specifications to engineering teams.

Where Can You Buy Prefabricated Metal Buildings in NC, SC, and VA?

Local expertise ensures compliance with regional codes and quick delivery. Hinton Buildings specializes in serving customers throughout North Carolina, South Carolina, and Virginia with tailored solutions and efficient installation.

What Are the Building Code Requirements in North Carolina, South Carolina, and Virginia?

Each state enforces wind, snow, and seismic design criteria per the International Building Code (IBC). Coastal areas of NC and SC may require hurricane-rated anchoring and higher wind pressures, while mountain regions in VA demand enhanced snow load capacities. Local permit offices verify adherence to these specifications.

How Does Hinton Buildings Serve Customers in These States?

Hinton Buildings provides on-site consultations, coordinate permit submissions, deliver factory-certified assemblies, and manage turnkey installations. Our regional engineering team adapts foundation and structural designs to meet municipality requirements, ensuring rapid project approval.

What Are Examples of Local Projects and Case Studies?

From a 2,400 sq ft agricultural barn in Orange County, NC to a 3,000 sq ft retail warehouse in Columbia, SC, our portfolio spans diverse sectors. Each case highlights customization details—color schemes, door layouts, and interior finishes—that illustrate the adaptability of prefabricated steel structures.

How Do Weather Conditions Influence Metal Building Choices in These Regions?

Hurricane-prone coastal zones require reinforced wind bracing and corrosion-resistant coatings, while inland areas with heavy snowfall benefit from steeper roof pitches and higher gauge steel. Awareness of local climatic factors guides material selection and structural engineering.

What Types of Metal Buildings Are Available for Specific Uses?

Different end uses demand unique features in steel building design. Selecting the right configuration enhances functionality and maximizes return on investment.

What Are the Features of Metal Garages for Homes and Businesses?

Custom metal garages offer clear-span interiors for vehicle maneuvering, roll-up door options for multiple bays, and integrated electrical conduit for lighting and power tools. Optional insulation and interior framing converts garages into climate-controlled workshops.

Probuilt Steel Buildings, Distinct Characteristics of Metal Carports, Garages, and Barns, [2022]

Features of Metal Garages

Custom metal garages offer clear-span interiors, roll-up door options, and integrated electrical conduit. Insulation and interior framing can convert garages into climate-controlled workshops.

How Are Metal Barns Designed for Agricultural Needs?

Steel barns include wide-span frames to store tractors and hay bales, loft additions for feed storage, and ventilation systems to maintain livestock health. Overhangs and covered work aisles protect equipment and personnel from weather exposure.

Big Buildings Direct, Metal Barns, [n.d.]

Features of Metal Barns

Steel barns include wide-span frames for equipment and hay storage, loft additions, and ventilation systems. Overhangs and covered work aisles protect equipment and personnel.

What Commercial Metal Buildings Suit Warehouses and Workshops?

Industrial structures feature high-capacity clear heights, crane support rails, and modular office bays. Reinforced concrete foundations and heavy-duty roof purlins accommodate overhead cranes, pallet racks, and material handling systems.

Commercial Metal Buildings Benefits & Versatility, [2020]

Commercial Metal Buildings Benefits

Commercial metal buildings are ideal for warehouses, manufacturing facilities, and retail spaces due to their durability, cost-effectiveness, and customization options. They offer open floor plans and can be designed to meet specific business needs.

Are Metal Workshops and Storage Buildings Customizable for Unique Needs?

Workshops integrate reinforced floors, mezzanines, hydraulic lifts, and specialized HVAC zones. Storage buildings adopt adaptable bay spacing, sliding partition walls, and automated door systems—tailored to sector-specific workflows.

What Are Common Questions About Prefabricated Metal Buildings?

Addressing foundational concerns helps clarify decision-making and streamline the inquiry process before moving toward quotation and construction planning.

How Long Do Prefabricated Metal Buildings Last?

Steel structures have expected service lives exceeding 50 years when coated metals receive routine inspections and minor refinishing. Warranties often cover corrosion and material defects for 20–40 years, reinforcing owner confidence in longevity.

Are Metal Building Kits Suitable for DIY Assembly?

DIY kits simplify assembly with bolt-together framing and clear installation manuals. Suitable for experienced owners or small contractors, kits still require concrete foundations and occasional professional support for larger spans or heavy gauge components.

What Maintenance Is Required for Steel Buildings?

Maintenance involves periodic sealant inspections, gutter cleaning, and repainting of high-wear areas. Steel does not rot or warp, and coated fasteners and panels typically need attention only every 10–15 years—keeping upkeep costs low.

How Do You Request a Quote or Start a Custom Building Inquiry?

Begin by submitting project details through Hinton Buildings’ online inquiry form or scheduling a phone consultation. Provide dimensions, intended use, and desired features to receive a tailored proposal that outlines costs, lead times, and next steps toward fabrication and installation.

Prefabricated metal buildings present an efficient, versatile, and durable alternative to conventional construction. By exploring available types, accurate cost factors, tangible performance benefits, and extensive customization options, you can align a steel structure with your precise needs. Regional expertise ensures compliance with local codes and climate challenges, while straightforward financing programs make ownership attainable. With clear insights into design choices and project planning, moving from concept to completion becomes a seamless process. Whether you aim to store farm equipment, protect vehicles, or expand commercial operations, prefabricated steel offers a future-proof solution backed by decades of proven performance.